Optical Ground Wire (OPGW)

Downloding OPGW spicificattion Catalog

An overhead ground wire is installed to protect phase conductors from lightning and reduce electromagnetic interference against telecommunication lines during the grounding of power lines.

An optical fiber can transmit a large amount of information in high speeds and suffers no electromagnetic interference because of its non-metallic characteristics. This advantageous feature makes it possible to construct long distance telecommunication lines with high reliablity.

Generally, OPGW has dual performance functions of conventional ground wire with optical fiber telecommunication capabilities.

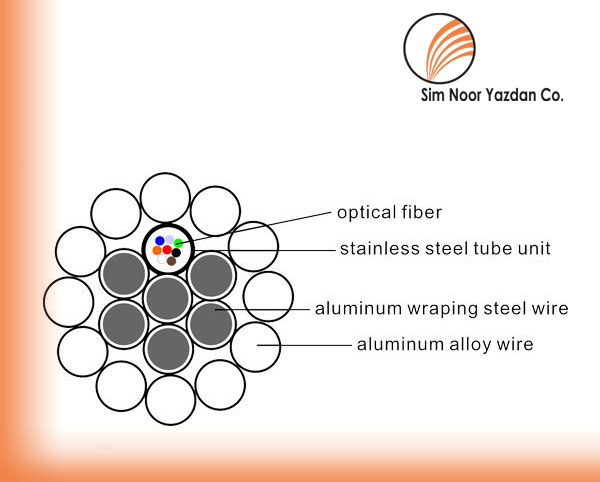

Typical Construction of an OPGW cable:

- The Optical Fibers

- The Stainless Steel central buffer tube.

- The Cable Armoring consisting of one, two or more layers of armoring wires.

A Cross-Section of OPGW

Features & Benefits

Our high quality standards for designing, testing and manufacturing with the highest grade materials available to ensure long-term reliability.

Maximum fiber counts up to 72 fibers with minimized cable diameter due to variable designs.

Superior optical performance over a broad temperature range

from -40 C to +85 C

Engineering support, supervising and providing its own line of accessory hardware.

Excellent tensile performance under cable elongation and contraction due to extreme tension and variation of temperature.

Moisture-proof jelly filled core for superior protection to the optical fibers due to hydrogen generation in metal structure.

Continuous and seamless tube for superior protection to the optical fibers from moisture and extreme environmental conditions such as lateral force.

Applicable Standards

Optical Fiber

- ITU-T G.650 / ITU-T G.652

- ITU-T G.653 / ITU-T G.655

- IEC 60793

Aluminum-Clad Steel Wire

- IEC 61232 / ASTM B 415

Aluminum Alloy Wire

- IEC 60104 / ASTM B 398

Complete OPGW

- IEC 61089 / IEC 60794

- IEC 60794-4

- ASTM B 416 / IEEE 1138

Steel Tube Specification

|

Item |

Unit |

Description |

|

Material |

|

Stainless Steel Tape |

|

Inner Diameter |

mm |

(2.6,3.1,3.6) +- 0.05 |

|

Outer Diameter |

mm |

(3,3.5,4.1) +- 0.05 |

|

Filling Component |

|

Water Repellent, Thixotropic |

|

Fiber Number |

|

24 |

|

Fiber Types |

|

G655 |

|

Elongation |

% |

Min. 2.0 |

|

Fiber Excess Length |

% |

0.5 - 0.7 |

Color Identification of Fiber in the Stainless Steel Tube Unit

|

Without Color Ring |

With S60 Color Ring |

With D80 Color Ring |

With S90 Color Ring |

||||

|

Fiber No. |

Color |

Fiber No. |

Color |

Fiber No. |

Color |

Fiber No. |

Color |

|

1 |

Red |

13 |

Red |

25 |

Red |

37 |

Red |

|

2 |

Green |

14 |

Green |

26 |

Green |

38 |

Green |

|

3 |

Blue |

15 |

Blue |

27 |

Blue |

39 |

Blue |

|

4 |

Yellow |

16 |

Yellow |

28 |

Yellow |

40 |

Yellow |

|

5 |

Gray |

17 |

Gray |

29 |

Gray |

41 |

Gray |

|

6 |

Brown |

18 |

Brown |

30 |

Brown |

42 |

Brown |

|

7 |

Violet |

19 |

Violet |

31 |

Violet |

43 |

Violet |

|

8 |

Aqua |

20 |

Aqua |

32 |

Aqua |

44 |

Aqua |

|

9 |

Black |

*21 |

Black (White) |

*33 |

Black (White) |

*45 |

Black (White) |

|

10 |

Orange |

22 |

Orange |

34 |

Orange |

46 |

Orange |

|

1 |

White |

23 |

White |

35 |

White |

47 |

White |

|

12 |

Pink |

24 |

Pink |

36 |

Pink |

48 |

Pink |

* Remark: The black color with color ring is changed to white color

OPGW Datasheet 10.5

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

at 16% UTS

at 72% UTS

OPGW Datasheet 12

OPGW ACS / 75.4 24/48 SM/NZDSF 12

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

at 16% UTS

at 72% UTS

|

OPGW ACS / 102.1 |

24 SM/NZDSF |

|

13.5 |

||

|

Item |

Technical Data |

Number |

Material |

Value |

Unit |

|

1 |

Tube |

1 |

SSLT |

3.0 |

[mm] |

|

2 |

Total number of fibers |

24 |

|

|

No |

|

3 |

Central tube |

1 |

Steel tube |

3.0 |

[mm] |

|

4 |

First layer roundwire |

5 |

ACS |

3.0 |

[mm] |

|

1 |

SSLT |

3.0 |

[mm] |

||

|

5 |

Second layer roundwire |

15 |

ACS |

2.25 |

[mm] |

|

|

|||||

|

6 |

Cable diameter |

13.50 |

[mm] |

||

|

7 |

Supporting Cross-section |

102.1 |

[mm²] |

||

|

7/1 |

Cross-section ACS |

102.1 |

[mm²] |

||

|

8 |

Cable weight |

701.4 |

[kg/km] |

||

|

8/1 |

weight of ACS wires |

681.5 |

[kg/km] |

||

|

8/2 |

weight of S.S TUBE |

19.0 |

[kg/km] |

||

|

8/3 |

weight of Grease |

0.9 |

[kg/km] |

||

|

|

|||||

|

9 |

Calculated breaking load |

123.1 |

[KN] |

||

|

10 |

Modulus of elasticity |

159.0 |

[kN/mm²] |

||

|

1 |

Coefficient of thermal expansion |

13.0 |

[1/K] |

||

|

12 |

Maximum tensile stress |

506.5 |

[N/mm²] |

||

|

13 |

Everyday stress |

193.0 |

[N/mm²] |

||

|

14 |

Permanent tensile stress |

868.3 |

[N/mm²] |

||

|

15 |

D.C. Resistance at 20 °C |

0.731 |

[Ohm/km] |

||

|

16 |

Conductive cross-section |

25.5 |

[mm²] |

||

|

17 |

Calculated IEC60857 Short Circuit current from 20 to 180 °C |

- at ( 0.5 ) s |

10.5 |

[kA] |

|

|

18 |

Calculated IEC60857 Short Circuit current from 20 to 200 °C |

- at ( 0.5 ) s |

11 |

[kA] |

|

.jpg)

.JPG)